Aurora Networks® (ANS) and RUCKUS® Networks are now Vistance Networks

In the early days of fiber deployment, building a reliable network required as much grit as it did during the engineering process. Field crews often worked under harsh conditions, huddled in makeshift tents to carefully join delicate glass fibers. Every splice demanded precision and patience, with dust and moisture and unpredictable weather posing constant threats to signal integrity. Protecting those fragile connections in the outside plant was one of the biggest hurdles service providers faced.

The early challenges

Fiber promised massive capacity gains over copper, but it came with new challenges. The first closures were often bulky and difficult to install. They required extensive training, specialized equipment and hours of labor to ensure a watertight seal. For technicians, every splice was high stakes—any contamination or misalignment could lead to signal loss, or worse, network outages, resulting in costly rework and frustrated customers.

Enter CommScope FOSC® solutions: A shift toward reliability

The introduction of fiber splice closures marked a turning point. Designed to keep splices protected against water, debris and temperature extremes, CommScope’s patented FOSC technology brought standardization and reliability to the field. Suddenly, fiber didn’t just work in controlled lab environments—it could survive in the real world. The earliest FOSC designs focused on ruggedness and protection, giving network operators peace of mind that once a splice was made, it would stay protected for decades.

The modern era of fiber closures

Fast forward to today, and the evolution is striking. Modern CommScope FOSC designs are not only hardened but also field-friendly, with modular components, tool-less entry systems and intuitive cable management, and scalable architecture resulted in crews working faster, with fewer errors and downtime.

These streamlined closures are purpose-built for today’s broadband realities—dense fiber counts, rapid deployments and networks that must scale quickly to meet insatiable demand. They are compact yet expandable, lightweight yet durable and engineered for both aerial and underground environments.

Looking ahead

As networks move toward automation, AI and predictive maintenance, the role of closures is poised to evolve once again. Just as splicing sleeves gave way to standardized FOSC systems, tomorrow’s closures will adapt to serve as both the guardians and the informants of the fiber network.

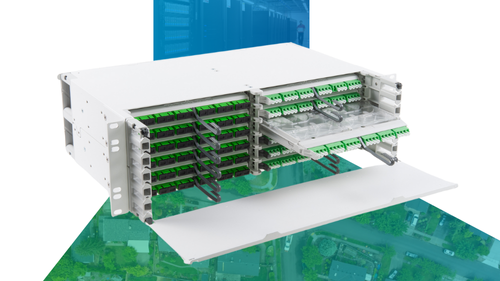

CommScope is already paving the way with innovations like the FOSC HD closure, engineered for high-density splicing in space-constrained environments. Its compact footprint helps reduce the need for additional handholes and manholes, lowering the cost per splice point and improving overall project ROI. Designed to integrate seamlessly with existing FOSC platforms, it maintains the trusted durability of the FOSC 400® and FOSC 450® closure series while enabling greater capacity and deployment flexibility.

Complementing this is CommScope’s next-generation pole mounting bracket, built for modularity and rugged performance. With integrated cable slack storage and multiple mounting options, it streamlines installation and supports a wide range of FOSC and outside plant closures—even in the harshest outdoor conditions.

Together, these solutions reflect a future where closures are not only tougher and smarter but also more adaptable to the demands of modern broadband expansion.

CommScope: The trusted name in fiber closures for over 30 years

The journey from splicing sleeves to today’s streamlined closures mirrors the transformation of the fiber industry itself and CommScope has been at the center of that evolution. From the very first FOSC closure designs that set the industry standard for durability, to today’s advanced, field-friendly solutions built for scalability and speed, CommScope’s FOSC solutions have consistently redefined what’s possible in fiber protection.

Our closures are more than just housings for splices, they are innovations that enable providers to build networks faster, protect investments longer and prepare for increasing intelligence and automation. With decades of proven performance in the field and a relentless focus on innovation, CommScope continues to drive both the past and the future of fiber closure technology, ensuring the connections that power our digital world remain strong, reliable and engineered for the future of broadband.

© 2025 CommScope, LLC. All rights reserved. CommScope and the CommScope logo are registered trademarks of CommScope and/or its affiliates in the U.S. and other countries. For additional trademark information see https://www.commscope.com/trademarks. All product names, trademarks and registered trademarks are property of their respective owners.