Website Maintenance Announcement – September 19–21

Activities begin at 6:00 PM CT on Friday, September 19 and continue through Sunday, September 21.

During this time, Product and My Product List functionality will be unavailable

Website Maintenance Announcement – September 19–21

Activities begin at 6:00 PM CT on Friday, September 19 and continue through Sunday, September 21.

During this time, Product and My Product List functionality will be unavailable

Patch cords can be the “weak link” in an end-to-end infrastructure solution. Connectors and patch cords are significant contributors to network performance. Fine ‘tuning’ these high performance components to each other, as well as variation control techniques, are required to enable reliable, predictable performance every time.

It is becoming a widely known fact in the cabling industry that patch cords can be the “weak link” in an end-to-end infrastructure solution. Historically, many focused on cable performance when making infrastructure decisions. However, connectors and patch cords have become significant contributors as cabling systems have evolved. Fine ‘tuning’ of these high performance components to each other, as well as variation control techniqu

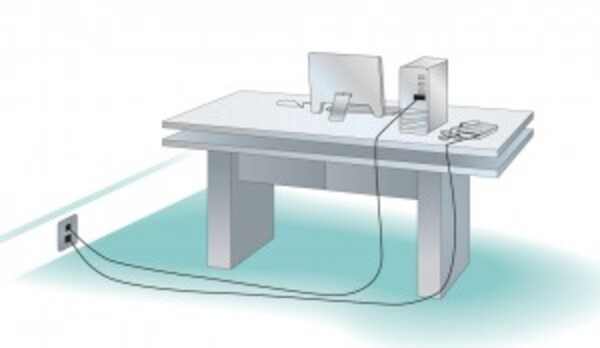

Testing of installed cabling has gained wide acceptance as a performance checking mechanism, and the technology has advanced to the point where testing up to 500 MHz is routinely performed quickly and accurately in the field. However the most widely used test configuration, the Permanent Link, was developed in standards to verify the performance of the installed link from patch panel to work area outlet. In other words, it specifically excludes the patch cords.

Most customers assume that the addition of ‘standard compliant’ cords will guarantee the delivery of the required end to end performance. Why would they think otherwise? How can such a simple looking, off-the-shelf product make a difference?

Significant strides have been made to cabling standards over the years to specify requirements for components intended to deliver the expected end to end performance even in a mix-and-match environment. However I believe it is important to note that the standards specify minimum requirements only, and do not cover all the coupling and reflection effects that may occur within or between components. In addition and as highlighted by an excellent blog post by Jim Hulsey (You get what you pay for), ‘standards compliance’ is a self certification which means anyone can make the claim, it is up to the customer to believe them.

Designing patch cords to overcome the “weak link” concerns

A patch cord is constructed with flexible cordage and a modular (RJ45) plug on each end. In order to deliver optimal performance, the characteristics of the cordage are carefully matched to the plug, including jacket type, thickness and overall outer diameter, the orientation of the pairs at each end prior to termination, the twist rate, the insulation diameter, the conductor diameter, and many others.

Poorly assembled plugs will deliver inconsistent performance and may exhibit intermittent continuity – a network manager’s worst nightmare! In extreme cases, badly assembled plugs may even damage the contact pins in cabling or switch ports, for example when the plug ‘blades’ are loose, too high or out of alignment.

The arrangement of each cable pair inside the plug must also be carefully controlled. This enables system vendors such as CommScope to tune jacks and plugs to achieve performance above the minimum stan dard requirements.

dard requirements.

CommScope has developed highly advanced modeling techniques to optimize channel performance, as well as sophisticated electrical, mechanical and manufacturing techniques to minimize the performance impact and variation that can result from sub-optimal matching of patch cords to the rest of the system. The system warranties offered by CommScope provide customers with an assurance of long-term performance beyond the minimum requirements of standards, as well as coverage in the unlikely event of quality defects.

Therefore, using ‘just any’ patch cord in a system may not only degrade performance but may prove to be a costly mistake in the event of a system failure, that may have been otherwise covered by warranty.