Single-mode optical fiber has several possible variants. The information being conveyed in the market regarding areas such as compatibility, splicing and cable construction varies greatly. This variation in information creates confusion and introduces the potential for a customer to use a specific type of cable that does not meet their expectations or requirements. Let’s look closer at single mode fiber cabling and some of the common misconceptions in the industry.

Single-mode optical fiber has several possible variants. The information being conveyed in the market regarding areas such as compatibility, splicing and cable construction varies greatly. This variation in information creates confusion and introduces the potential for a customer to use a specific type of cable that does not meet their expectations or requirements. Let’s look closer at single mode fiber cabling and some of the common misconceptions in the industry. OS1 and OS1 ZWP

OS1 single mode fiber is based on the fiber glass specification ITU-T G652.A or B (equivalent to using IEC 60793-2-50 Type B1.1 fibers). This specification has standard attenuation of 1 dB/km maximum across both 1310 nm and 1550 nm wavelengths. OS1 zero water peak single mode fiber is based on theglass fiber specification ITU-T G652.D. This specification has standard attenuation of 1 dB/km max and a low water peak above and below the 1383 nm wavelength and controlled polarization-mode dispersion.

The zero water peak is important because it allows forcoarse wave division multiplexing (CWDM), thus substantially increasing the bandwidth potential of the single mode fiber. Low water peak fiber is also marketed as zero water peak. International standards will address this potential confusion shortly by creating a new fiber type known potentially as OS1a. OS1a will have standard attenuation of 1 dB/km, but measured in three wavelengths:

- 1310 nm

- 1383 nm

- 1550 nm

OS2

The OS2 specification has a much lower attenuation of0.4 dB/km maximum at three wavelengths (1310 nm, 1383 nm and 1550 nm) and low water peak. There are two types of OS2:

- Type B1.3 of IEC 60793-2-50 (ITU-T G652D), specified out to 1550 nm

- Type B6 a using IEC 60793-2-50 (ITU-T G657A and G657B), specified out to 1625 nm

Type G657A/B is commonly referred to as bend insensitive fiber or reduced bend radius fiber. It is capable of a smaller minimum bend radius without degrading the attenuation of the fiber.

Bend insensitive fiber cables are compliant with G652.D standards so they can be spliced and connected to G652.D fibers without excessive loss. All core/cladding sizes are the same (9/125 microns); however, some fusion splicing machines may suffer difficulty in determining the fiber type of the bend insensitive cable when trying to splice to a more typical G652D cable. This is largely because of the “trenches” that are used around the nine-micron core of the fiber, enabling the fiber cable to bend much more. The fusion splicer can be set to cladding alignment to alleviate this issue.

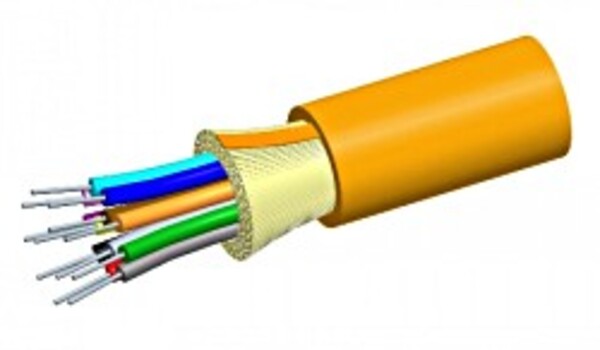

A common misunderstanding in the market is the ability of tight buffered fiber cable construction to be used with OS2 fiber and maintain full performance and compliance.

Whilst it is true that buffering cable with aramid yarn/Kevlar construction puts higher stress on the glass compared to a loose tube gel fill cable or loose buffer cable, CommScope spends much time developing and implementing innovative ways of encasing the glass fibers within the yarn/ Kevlar weave to provide a robust and protected environment.

Further strengthening the cable with central strength members or outer protection materials in and around the cable sheath helps assist with enabling a stronger cable with both torsional and tensional strength. Combine this with decades of Research and Development across both cable and connectivity, and cable performance is maintained with 100 percent compliance with the aforementioned IEC and ITU-T Standards being achieved. Paying attention to all details of the cable construction, not just the glass alone, ensures the customer’s expectations are consistently met to the highest quality in the industry.

What else would you like to know about these fibers?